High-Performance Electric Motors for Sale

Explore reliable electric motor solutions designed for maximum efficiency, durability, and performance, and customized to your specific application.

Robust, compact, customizable

Certified Supplier- Find Out Different Types of Electric Motors

We offer a wide range of small and large, low-voltage and high-voltage electric motors—including AC motors, DC motors, BLDC motors, stepper motors, synchronous motors, VFD motors, explosion-proof motors, servo motors, and more—suitable for various industries. Contact our sales team today or explore our selection of high-efficiency motors to find the perfect solution for your business needs!

Hot Products for Sale

High-Speed Precision Industrial Motor

| Flow Rate: 1000 RPM to 6000 RPM |

| Torque: 10 oz-in to 2000 oz-in |

| Power / HP: 0.1 HP to 500 HP |

| Efficiency: 85% to 98% |

Low Voltage Synchronous Motor

| Speed / RPM: 1000 RPM to 6000 RPM |

| Torque: 10 oz-in to 2000 oz-in |

| Power / HP: 0.1 HP to 500 HP |

| Efficiency: 85% to 98% |

Hybrid Stepper Motor

| Speed / RPM: 500 – 3000 RPM |

| Torque: 0.1 – 4.0 Nm |

| Power / HP: 0.1 – 1.0 HP |

| Efficiency: 80% – 90% |

Brushless Servo Motor

| Speed / RPM: 1000 RPM to 6000 RPM |

| Torque: 0.1 – 50 Nm |

| Power / HP Power Sou: 0.5 – 15 HP |

| Efficiency: 85% to 95% |

High-performance BLDC Motor

| Speed / RPM: 3000 – 8000 RPM |

| Torque: 0.5 – 100 Nm |

| Power / HP: 0.5 – 50 HP |

| Efficiency: 90% – 98% |

Standard Three-Phase Induction Motor

| Speed / RPM: 1000 – 3600 RPM |

| Torque: 0.5 – 500 Nm |

| Power / HP: 0.5 – 500 HP |

| Efficiency: 85% – 95% |

Explosion-Proof Three-Phase Motor

| Speed / RPM: 600 – 3600 RPM |

| Torque: 0.5 – 2000 Nm |

| Power / HP: 0.5 – 500 HP |

| Efficiency: 85% to 95% |

VFD Motor

| Speed / RPM: 1000 – 5000 RPM |

| Torque: 0.5 – 1000 Nm |

| Power / HP: 0.5 – 500 HP |

| Efficiency: 85% to 98% |

More Different Types of Electric Motors Are Available here… Tell us your needs and contact us today!

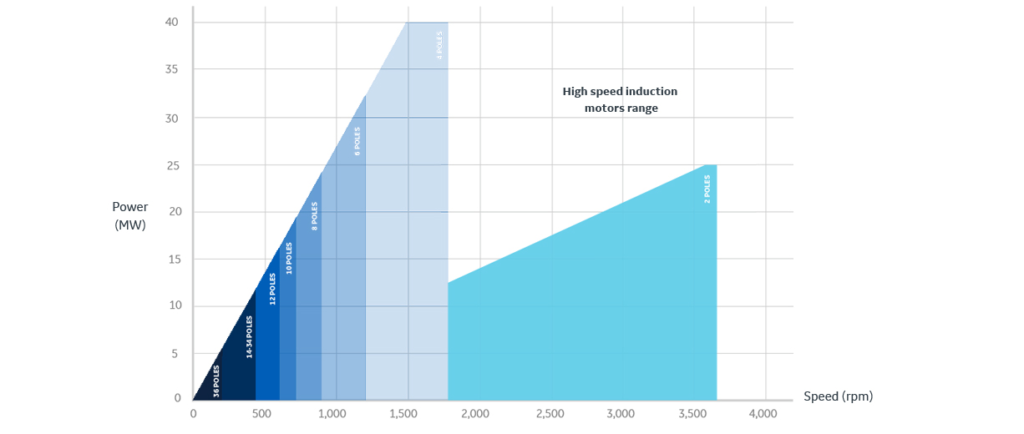

Power Speed Range

Trusted Products Brand

Why Choose BESQO MARINE?

“We deliver reliable, compact, and tailor-made electric motors, engineered to provide exceptional performance and perfectly match your unique requirements.”

Best Quality

Our proven expertise and long-standing experience enable us to consistently deliver the best solutions to our clients.

Exact Price

We aim to provide high-quality products with the best value for your investment.

Satisfaction Response

We take pride in customer satisfaction—it's what drives us forward.

On-Time Delivery

Timely Delivery with quality work is what we are known for.

What Our Clients Are Saying